EDILOG, THE NEXT GENERATION LOG STACKER

With electric operation and an innovative design that maximises the operator’s experience, increases sustainability and reduces emissions, EdiLog takes the position as the next generation log stacker. Modern technology ensures reliability and reduces operating costs for a production critical function, with the mission of operating around the clock, seven days a week. EdiLog embraces modern technology and takes sustainability to a whole new level.

MAXIMUM CAPACITY AND PERFORMANCE WITH GREATEST POSSIBLE SUSTAINABILITY

Our will, ability and great interest in developing technology has resulted in the electrically powered concept, EdiLog, the next generation of log stacker. The machine environment attracts skilled operators who rightly place high demands on the workplaces of the future, at the same time that electric operation gives financial and environmental benefits.

Log stackers play a leading role in the forestry industry and need to operate flawlessly around the clock in order to keep production going. A sustainable environment for people in and around the machine is then of the utmost importance. Continuous operation with traditional diesel engines produces a significant amount of carbon dioxide emissions and means high fuel costs. In addition, maintenance and repairs require time, which means costly interruptions to the work flow in this type of industry. To that can be added the costs of repair work, spare parts and lubricant. By focussing on quality and functionality, we have used modern technology to transform a traditional machine into a future-proof version: EdiLog.

THE OPERATOR’S ENVIRONMENT OF THE FUTURE

A skilled workforce is an important future issue for every employer, not least within the forestry industry. EdiLog’s attractive interior and exterior working environments meet both the demands and wishes of machine operators who want optimal conditions to deliver quality on time..

Improved view, camera technology that replaces mirrors, smooth hydraulics and the possibility of making personal settings give complete control of the task. Reduced noise during operation increases the comfort level further.

CHEAPER OPERATING COSTS, LESS NOISE

EdiLog is powered by an electric motor, which is mounted directly on the front axle. A diesel engine powers a generator and hydraulic pumps at a greatly reduced speed, which we have adapted to increase fuel efficiency and to exploit the torque in the best possible way. The lower RPM also reduces noise levels and all specified outputs are achieved without affecting the performance of the machine. By removing the gearbox we have eliminated the most complicated and maintenance intensive mechanical component of the machine.

POWERED BY WELL-PROVEN ELECTRIC MOTOR

The electric motor in EdiLog is well-proven. Energy is stored in ultracapacitors that give the application better performance than batteries and that have a service-life equal to that of a diesel engine.

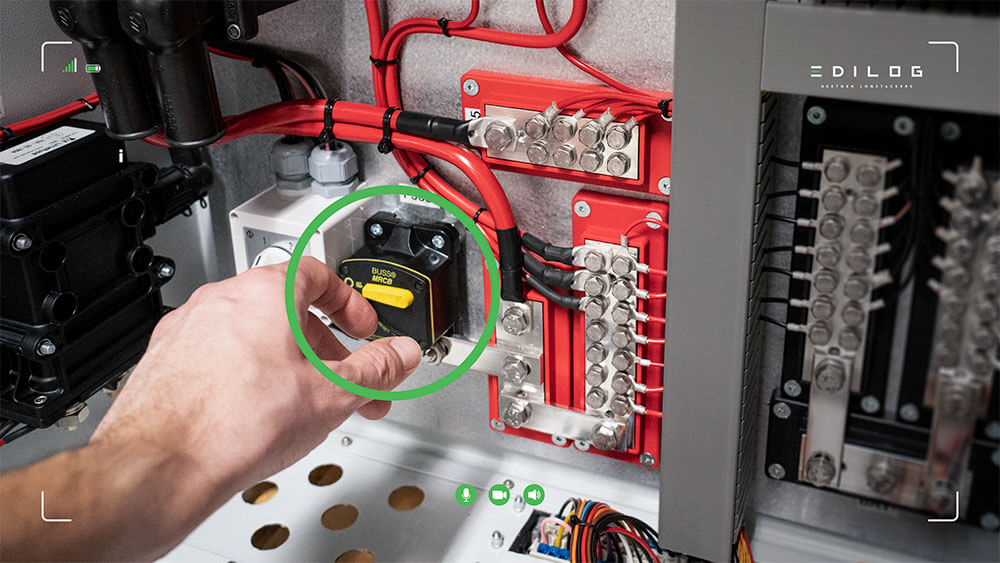

MONITORING FOR FAST PROBLEM SOLVING

EdiLog’s technical design makes it possible to monitor, diagnose and analyse any faults. The system provided therefore gives unsurpassed potential to resolve any problems quickly. We can monitor each machine digitally from our facility and offer that service as assurance to our customers.

TIMBER GRAPPLE WITH THE RIGHT DIMENSIONS

The timber grapple is dimensioned for future, larger rail wagons, and can therefore easily unload future timber loads in one simple operation. A standard sized grapple requires repetitive manoeuvres resulting in double operation for each wagon, which is both time consuming and devastating from an environmental point of view.

EQUIPPED FOR ADVANCED TROUBLESHOOTING

Advanced equipment facilitates troubleshooting, while enabling technical diagnostics, measurements and follow-ups. The option of a complete upgrade after 3–5 years increases the sustainability and generates a new warranty period at a considerably lower cost than a new investment.

THE OPERATOR’S ENVIRONMENT

EdiLog offers a modern operator’s environment that takes full advantage of the available technology. Both steering wheel and rear view mirrors are optional because EdiLog is lever controlled, like an excavator, and camera technology gives the operator all round visibility. The sound environment is also excellent thanks to the reduced noise level.

SMOOTH DRIVING EXPERIENCE

Stepless acceleration via the accelerator pedal.

UNOBSTRUCTED VISIBILITY

Unobstructed visibility through shatter proof and heat-repellent glass.

CLEAR DISPLAYS

The operator manages settings and monitoring via displays.

SAFE DRIVING EXPERIENCE WITH ALL ROUND VISIBILITY AND LOW NOISE LEVEL

The cab is the operator’s workplace and EdiLog takes advantage of the latest technology to create a modern working environment both in and around the machine. A steering wheel is optional, as are rear view mirrors. EdiLog is lever controlled, like an excavator, and uses camera technology to give the operator all round visibility.

Shatter proof and heat repellent glass mean that safety grilles, which were previously required to protect the operator and obstructed visibility, are no longer needed. EdiLog has unobstructed views.

SMOOTH OPERATION WITH FULL CONTROL

The driving experience is extremely important for the operator’s well-being and comfort. Therefore, we have worked hard to get EdiLog to feel like a machine with a normal gearbox, even though it does not have one. Acceleration is regulated by the accelerator pedal, which has a different function compared to a conventional machine. It regulates the speed steplessly, without transmission shunt and in conjunction with the hydraulic speed.

Excellent sound environment. The machine is so quiet that the only thing the operator hears is the sound of the tyres.

SETTINGS AND CONTROL VIA DISPLAYS

The machine operator can make most settings on a display and can save personal settings for their next shift. Monitoring is performed with another display.

ENTIRE OPERATOR'S MANUAL IN YOUR POCKET

The complete operator's manual is available via the cab’s PC. We also recommend that the operator downloads it to his/her smartphone for easy access to the information at all times.

LET US CONTACT YOU

Leave your contact information and we'll get in touch.

MAINTENANCE

The installation of an electric motor in EdiLog requires advanced programming, but its function is considerably simpler than for a conventional stacker with a gearbox. By reducing the number of parts in the powertrain, we have managed to maximise reliability and minimise maintenance. An unrivalled monitoring system is included and using smart glasses, our experts can see through your eyes and give you the correct guidance straight away.

RELIABLE

Fewer parts in the powertrain maximises reliability.

REDUCED MAINTENANCE

Electric operation means a drastic reduction in maintenance.

GUIDE VIA SMART GLASSES

AR glasses allow our experts to see through your eyes.

MAXIMUM RELIABILITY WITH REDUCED MAINTENANCE

High reliability and productivity are essential in a log stacker. Our installation of an electric motor requires advanced programming, but its function is considerably simpler than for a conventional stacker with a gearbox.

By reducing the number of parts in the powertrain, we have managed to maximise reliability and minimise maintenance. Thanks to a direct drive, the universal joint is the only part that requires lubrication maintenance a couple of times a year.

REDUCED MAINTENANCE

Even a hybrid machine requires some maintenance, but EdiLog’s design ensures that it is kept to a minimum. Tests and qualified calculations indicate an expected saving of about one cubic metre of lubricant per machine each year, for example.

INCREASED MONITORING

Maintenance also includes the option of monitoring, diagnosing and analysing any faults. The supplied system gives an unsurpassed opportunity to anticipate and quickly resolve future problems. We offer monitoring from our own facility, which also allows us to be proactive and propose actions that provide even more efficient operation in good time.

LET US SEE THROUGH YOUR EYES

With the help of smart glasses, our experts can be there for you right away, wherever you are. As a service technician, when you are going to perform an action and you put on the augmented reality glasses, we can then see what you see and can guide you so that you feel completely reassured in carrying out the task.

LET US CONTACT YOU

Leave your contact information here and we'll get in touch.

OWNERSHIP

EdiLog offers modern technology that considerably increases the sustainability of the machine compared to its competitors. Count on a drastic reduction of CO2 emissions and cost savings with minimised fuel and maintenance costs.

STRONG ENVIRONMENTAL PROFILE

Electric operation reduces the emission of carbon dioxide.

COST SAVINGS

Reduced fuel and maintenance costs.

BENEFICIAL UPGRADE

Upgrade model renews the benefits of the stacker.

OWNERSHIP WITH SUSTAINABLE FINANCIAL AND ENVIRONMENTAL BENEFITS

Traditional log stackers are known for low levels of technology and a relatively high price. EdiLog offers modern technology that considerably increases the sustainability of the machine compared to its competitors.

EdiLog’s concept has grown out of a strong desire to develop a product critical function for a sustainable future, with the operator’s needs in focus. Because we realised that the possibilities for energy savings were huge, we conducted a study to explore them. We used the results to build our first stacker, which met our expectations.

REFINED FUNCTIONS WITH QUALITY ASSURANCE

We have used modern technology to transform a traditional machine into a future-proof version, with quality and functionality as a starting point. Safety awareness permeates the design. The machine is CE labelled and we put a lot of effort into making the new generation of log stacker even safer.

PROVEN TECHNOLOGY GIVES A HIGH LEVEL OF OPERATIONAL RELIABILITY

EdiLog’s electric motor is well-proven and we ensure a high level of operational reliability by following the latest standards applicable within the area. We offer training for service technicians to be able to perform maintenance tasks safely.

The operator’s environment has been designed in close collaboration with skilled machine operators. Continued development is our own sustainable driving force and through our own operation of the production facility in Timrå, we are in complete control of performing quality assurance on each machine.

SUSTAINABLE ENVIRONMENTAL BENEFITS AND EXCELLENT COST SAVINGS

EdiLog’s electric operation means huge fuel savings; advantageous to both you and the environment. Count on a reduction of around 120 tons of CO2 emissions per year for a machine that is in operation 24 hours a day, seven days a week. Savings can also be made thanks to the reduction in maintenance costs.

We have come a long way in increasing the energy efficiency of machines – but we are not satisfied. Continued reduction in energy consumption is the direction that everyone has to go in and we already have well-founded ideas on how to achieve that for EdiLog.

Our upgrade model has been developed to add another cost-conscious sustainability dimension. After 3–5 years of operation, EdiLog offers a full machine upgrade where we reuse the steel construction and replace the powertrain and cab. This results in a completely upgraded stacker with a new warranty included, at a very attractive price compared to investing in a brand new vehicle. This also helps us save the earth’s resources together.

LET US CONTACT YOU

Leave your contact information here and we'll get in touch./p>

SPARE PARTS AND SERVICING

We have what you need in stock for fast delivery. EdiLog's customised production facility is strategically located close to assured transport. Our digital service portal can be accessed around the clock.

SPARE PARTS IN STOCK

We stock what you need.

FAST SERVICE

Strategic location for assured transport.

CONVENIENT SERVICE PORTAL

Guaranteed updated information.

WAREHOUSING AND DELIVERY FOR MAXIMUM OPERATION

A good supply of spare parts for fast delivery is crucial for continued profitable operation. Therefore, EdiLog's production facility in Timrå is specifically designed to meet all current service and warehouse needs. We have what you need in stock and it is sent from a strategic location for fast transport by truck, plane or train. Our goal is to ensure maximum uptime for your machine.

DIGITAL SERVICE PORTAL ALWAYS UP-TO-DATE

We can guarantee constant access to updated data through EdiLog's digital service solution. When you log in to our service portal, you get direct access to the latest information and never have to worry about making updates yourself. We handle all that centrally.

The portal contains all the machine data you need, such as operator and workshop manuals as well as spare parts manuals. In it you can easily search for current parts by clicking down the machine tree on the screen. Choose to add the relevant parts to the shopping basket and then order them directly without having to note the item number or similar. This eliminates the risk of misunderstandings or mistakes. It should be easy!

LET US CONTACT YOU

Leave your contact information here and we'll get in touch.

NEWS

Nextgen Logstackers uses Nextgen technology

28 October, 2022With state-of-the-art technology, we can, with your smartphone help you with problem solving in the field. Our knowledge and.Fuel cost has skyrocketed

21 October, 2022Due to the fuel prizes, we will share the knowledge we have gained with our extensive measuring of EdiLog..CONTACT

EdiLog offers profitable ownership with easy maintenance that is beneficial to your business and the environment. At the same time, a high level of cab comfort, user-friendly technology and exclusive driving feel, with modern convenience makes EdiLog the first choice for skilled operators. Contact us for a long-term, sustainable and reliable log stacker, which ensures productivity.

Kjell-Arne Engberg

CEO/Marketing

kjell-arne.engberg (a) edilog.se

060 51 55 51

Ann-Charlotte Gustafsson

Site manager

ann-charlotte.gustafsson (a) edilog.se

060 51 55 97